Water recycling / Wasser Recycling for printing / graphic industries

The necessity of complying with standards for environmental protection has arisen also in the Graphic fields for a long time.

Hence, it has been studied to realize how to solve environmental problems and to reducing operating costs.

Among other already marketed products, there are wash water recycling systems for Film Processing Machines:

ECO 80F and for Offset Plates: ECO 80L and ECO 60/20.

Thanks to the water recycling systems ECO, processing machines for films and for offset plates can be installed in whatever ambient, even if connections for water inlet and outlet are not present.

They are easy to install and can be applied to all processing machines on the market.

ECO 80F: Expressively developed for wash water treatment and recycling in Rapid Access and Lith automatic processing machines. Closed circuit operation. It avoids excessive water consumption and pollution of the drainage system. In fact, polluted water, after being properly filtered, is sent again to the tank to be used in a circuit.

ECO 80F has 80 liter water capacity, quick and easy replacement of filtering cartridge.

ECO 80L: Same features as 80F but developed for treatment of wash water in offset plate processing machines.

ECO 60/20: Expressively developed for wash water treatment and recycling in offset plates automatic processing machines. Closed circuit operation. Avoids excessive water consumption and pollution of the drainage system. After being properly filtered, water is sent again to the tank to be re-used.

Water recycling system ECO 60/20 consists of two tanks of 60 and 20 liter capacity. One contains wash water of plates and the other wash water of gumming rollers. Waters are submitted to two filtering processes: A mechanical one, through a polypropylene cartridge and a chemical one, passing through resins at ion exchange thus maintaining the correct pH value through active carbons, thus allowing a partial water decoloration. Quick and easy replacement of filtering cartridge.

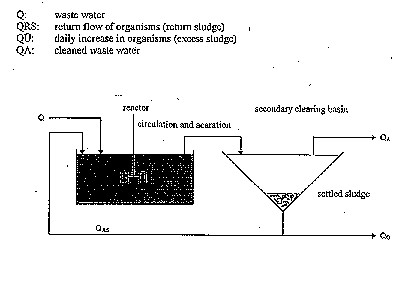

The BIO water recycling systems were inspired by nature and differ significantly from the known technical water treatment systems such as waste water separation, flotation systems or ultra filtration systems. In principle the system is designed as simply as imaginable, requires minimum operating costs and is extremely ecological. Practically no chemicals are required for treatment of the water.

The BIO water recycling systems can be operated using the cycle

principle and is suitable

for practically all types of waste water from vehicle washing. The use

of BIO systems is

recommendable at all places with much water consumption. This includes

all portal and

tunnel type washing systems and wash-yourself bays, BIO systems can also

be a real

alternative to conventional waste water systems even in manufacturing or

service halls

such as in motor vehicle workshops.

A special feature of BIO systems is that micro organisms remove tensides

as well as they

remove hydrocarbons, which is particularly important for reuse of the

industrial water. We

recommend to use MC3 - detergents with most compatible tensides.

Water recycling for car wash plants

| Phone : | +49 6128 970-817 | |

| Fax : | +49 6128 970-818 | |

| Postal Adress : | Neuhofer Strasse 7, | |

| D - 65527 Niedernhausen 2 | ||

| EMail : | info@Niebergall.de |

![]()